29 January 2026

For over 65 years, Jeanneau has combined savoir-faire, organisation, and rigorous standards to offer reliable, high-performance, durable sailboats. In our offices and workshops, from 3-D design to launch – including moulding, assembly, and numerous inspections along the way – everything has been designed to guarantee high quality standards. In this article, join us as we delve into the major steps in the construction of a Jeanneau sailboat.

Copyright: Raphael Dautigny

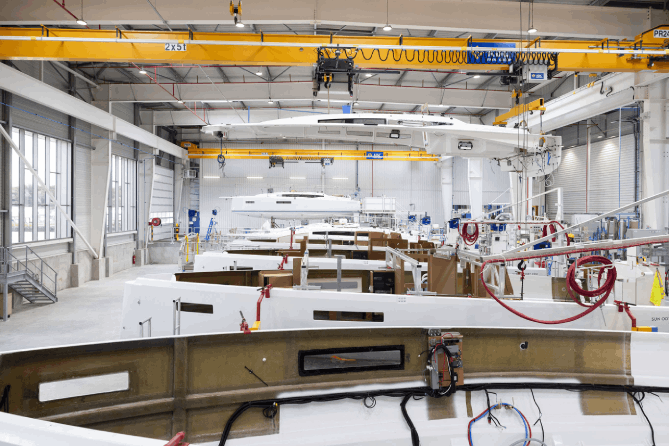

Take, for example, the Jeanneau production site in Cholet, France, where our 38- to 50-foot monohulls are built: how is a boat like the Sun Odyssey 415 constructed?

Matthieu Quelin, who is with Jeanneau Premium Service and responsible for customer visits to our various production sites, has agreed to discuss in detail the steps in construction.

From Concept to Mould: First Steps in the Construction of a Boat

Project Development, 3-D Modelling and CAD

The birth of a Jeanneau always begins with a rigorously structured pre-project phase, serving to progressively refine the initial drawing, the technical decisions, and the production requirements.

At this stage, Jeanneau engineering and design teams collaborate closely with naval architects – for the Sun Odyssey 415, Marc Lombard – to translate a cruising intention into a concrete plan. With Computer Assisted Design (CAD), volumes of living space are modelled in 3-D. We anticipate the handling and seakeeping of the future boat on the water, then the principal mould is prepared, and it is used to create the hull and the deck.

Technical Milestones and Developing the Mould

The Sun Odyssey 415, at this step, was developed as an evolution of the Sun Odyssey 410 – functional, clever, and versatile, for smooth, carefree sailing. In this phase, requirements related to the materials, structure, interior furnishings, and ease of assembly are integrated.

Moulds are designed to last for multiple years: they are created for each boat model with extreme precision, and they not only determine the boat’s form, but also its regularity, as well as the quality of parts produced in a series.

Fibreglass Moulding and Lamination

Moulding constitutes the first concrete step in the construction of a boat: with the mould, the forms drafted in 3-D become reality. For the Jeanneau Sun Odyssey line, moulding of the majority of the composite parts – hulls, decks, bulkheads, technical parts, etc. – incorporates vacuum moulding technology, using both infusion and injection moulding techniques.

The composite parts of the Sun Odyssey 415 are created in multiple layers, like a millefeuille pastry: the gelcoat is first sprayed into the mould to guarantee a regular finish and initial protection. Next, a barrier coat of fibres and resin make the part watertight, then layers of fibreglass are reinforced using sandwich construction. Using an infusion moulding procedure ensures the production of lightweight, robust parts with high regularity.

Each moulded part is subject to visual and tapping checks upon unmoulding. Any eventual defects are repaired immediately to limit retouching. The moulds themselves are maintained and reassessed regularly, in function with detected wear.

From Raw Wood to Onboard Comfort: Woodwork by Jeanneau

Woodwork, Modules and Subassemblies

At Jeanneau, marine woodwork is one of the historic pillars of our savoir-faire, inherited from the shipyard’s inception and from the woodworking trade of the first partners of Henri Jeanneau. In parallel with the work done in composites, our woodworking teams prepare the woodwork that will make up the boats’ interiors.

Furniture, floorboards, cabins, companionways, and chart tables are created from solid wood, marine plywood, or synthetic materials. The work is entirely done, from A to Z, by Jeanneau teams, starting with raw wood. This includes the cutout, treatment, and varnishing phases.

The cut-out phase entails cutting out and finishing the composite parts with precision, using a large-scale, digitally controlled, 5-axis CNC machine. The parts are then finished by cycles of sanding and polishing.

Preparation in the Wood Shop: Artisanal Skill at an Industrial Scale

Once the various elements of the boat have been prepared, they are preassembled in the form of modules, then tested and adjusted before reaching the production site. The time on the assembly line is reduced, and a homogenous finish is guaranteed on all the boats.

Assembly, Incorporating Each Element with Precision

An Assembly Line Designed for Smooth Operation

Hull, deck, woodwork modules, technical systems, deck hardware… on the assembly line, all the parts come together to give the boat her definitive form.

In Cholet, the production site where the Sun Odyssey 415 is produced, the hull arrives on a track in an area where teams are responsible for installing the basic technical elements:

- the engine

- the tanks

- the conduits

- the electrical system

- the plumbing

...

Future owners can, of course, visit the production facility and witness all the steps in construction of their boat.

Combining Elements to Complete the Structure

The modules, or subassemblies – the cabins, the technical spaces, the head and shower compartments, the companionway, the chart table, etc. – are then progressively integrated. Next comes the moment when the deck, already fitted with windows, linings, winches and deck hardware, is adjusted and attached to the hull.

Throughout construction, the assembly line is fluid, rhythmic, unhurried: the pace is defined in advance according to production planning. On a single line, you may find a Sun Odyssey 415 and a Sun Odyssey 440, side by side, each advancing at its own pace, always with the same exacting quality standards.

Quality Control: A Rigorous Process

Meticulous Inspection of Each Element

The common thread at Jeanneau, quality is an integral part of each phase in construction. On the production line, each time a boat advances, it does so by passing an inspection by a quality controller of the elements installed. Systematic inspections examine installations to ensure the correct fit and finish of the assembled elements and to check for the presence of any defects.

Learn more: Jeanneau Warranties, Spare Parts, and After-Sales Service… How Jeanneau Makes the Difference.

Repairs and Adjustments Prior to Delivery

Any necessary retouches or modifications are done, as needed, during the construction process, to guarantee their reliability. Quality records enable precise monitoring and full traceability.

Once the boat is fully furnished and equipped, it leaves the production line and moves to another building for finishing. Our teams make the last adjustments and prepare the boat for final testing.

From Launch to Taking Delivery of the Boat

Pool Testing and Verification of the Trim

Upon leaving the production line, the Sun Odyssey 415 is tested in a test pool. Like all Jeanneau boats!

At this step, we verify the trim according to the chosen options and configuration of the boat, its watertightness, both above and below the waterline, proper function of the engine and onboard systems (electricity, water, air conditioning, electronic instruments…) and, of course, the buoyancy of the boat.

Last Step to the Dealership

Once the dealer approves a transport date for the boat, the hull number (HIN) is engraved in the gelcoat. In a final step, the Jeanneau crew place the last elements on board and proceed with wrapping the sailboat in its protective cocoon before transport – either on a truck or in a container, in function with the destination.

Jeanneau Savoir-Faire in Boat Construction

Since 1957, at Jeanneau, reliability, onboard comfort, and longevity of our boats are at the heart of each project. Behind each sailboat delivered, there is a shipyard with highly skilled people, a great deal of discipline, and especially, a shared passion.

Jeanneau sailboat construction balances artisanal skill, technology, and industrial methods. Assembly of each model is based upon a rational process, involving numerous specialised technicians: fibreglass technicians, woodworkers, electricians, mechanics… several hundred people work together on the construction of a single boat!